For well over a year, the pandemic made people more attentive to their sniffles and coughs, or they would actively avoid those who might be standing too close for comfort. A new device developed in Southwest Florida and tested at Florida Gulf Coast University (FGCU) is helping alleviate some of that angst by cleaning germs from the air we breathe.

When the pandemic began, leaders at Cape Coral-based Energy Harness Corp. were anxious to get back in the office and tackle potential solutions to fight COVID-19. So they took their expertise in lighting and applied it to a new concept that could help the community. The result is the Active Airflow UV-C Fixture, designed to eliminate airborne pathogens like COVID-19.

“We knew LED light fixtures. We have built thousands of them, and we have a background in ultraviolet light,” said Peter Lehrer, Energy Harness senior vice president. “So we put those two together, and by the end of April 2020, we designed a fixture that would operate inside a classroom, office space or waiting room. It can operate while people are in the room.”

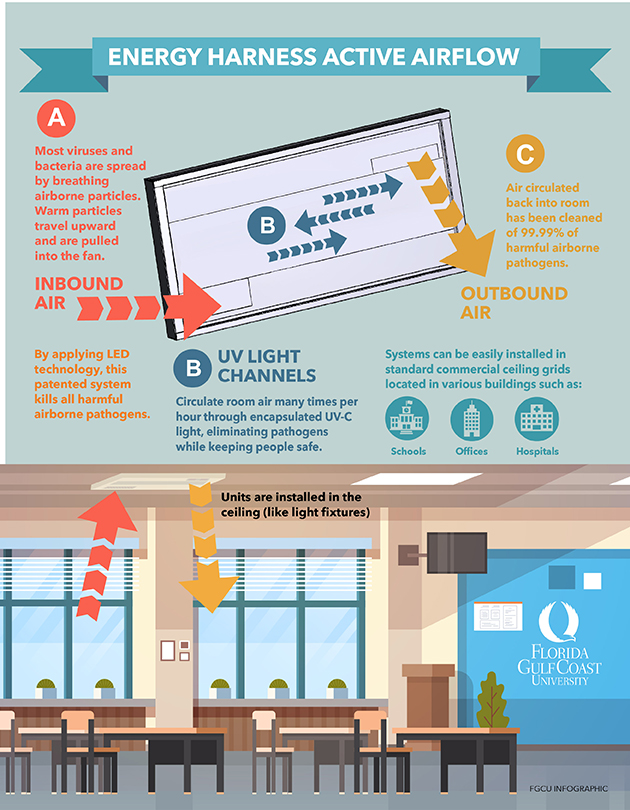

The Active Airflow UV-C Fixture is installed into a ceiling grid, generally found in schools or offices. The device circulates air in the room, and when it passes through the UV-C light chamber, the pathogens are killed and clean air is then released back into the room.

So how do we know the technology works? Enter FGCU.

FGCU bioengineering alumnus Nicolas Metro is one of Energy Harness’ newest hires. After graduating in spring 2020, Metro started work mid-pandemic as a products engineer and dove into the fixture development. He knew the lab in the U.A. Whitaker College of Engineering at FGCU would be the right place to test this new technology.

“I thought, ‘What better way to prove the efficacy of this product than to use the technology at FGCU?’” explained Metro. “We did send it off to third-party certifiable labs, but that takes a lot of time in a world where things are changing rapidly. We needed results quickly, and FGCU was there to help us in the beginning stage.”

As a research lab overseas tested the device on live SARS-CoV-2, Dr. Chris Geiger, associate professor and chair of the Department of Bioengineering, assembled a team of undergraduate students to verify the UV technology. With Metro’s help, they began experiments to determine whether or not UV light would kill types of surface-level bacteria, like E. coli, or prevent them from growing.

“This is what we should be doing. As a regional comprehensive institution, the opportunity to engage the community in meaningful activities, whether that’s research or internships, not only benefits the community partners, but also our students,” Geiger said. “That’s really the FGCU effect in action.”

Students worked through the summer, reading literature and researching ultraviolet light and its impact on pathogens. In the fall, testing began on the first prototype. Now they have helped prove the fixture is 99.99% effective at killing COVID-19.

“It was cool to work on something that was actually going to affect the community,” said Samantha Bellomo, a senior majoring in bioengineering and one of the undergraduate students working on the project. “Being a student, a lot of it is reading books and doing projects, but it’s easier to understand the processes when you’re able to get hands-on experience.”

The Active Airflow UV-C Fixture is now on the market. Another Energy Harness team member in charge of getting the fixture into the marketplace and installed in as many ceilings as possible is recent FGCU bioengineering graduate Lorenzo Battista. He joined Energy Harness after graduating in December.

“The students have just as much of an impact. They can say that they tested a device that keeps people safe,” said Battista. “It’s cool to bring it all together.”

The two grads are proud to have hit the ground running in their careers, and they credit part of that success to their time at FGCU. They want engineering students to realize the versatility of their degree and how their skills can be an asset in solving some of the most pressing issues.

“It will be nice to offer students insight into what they may not know about this area. That (employers) are looking for bright minds to come and work on the next big thing,” said Metro. “I’d love to be at an FGCU career fair with my colleagues, getting the next generation excited about what’s possible.”